PROCESS

Maximum Effect, Minimum Means

VARIABLES

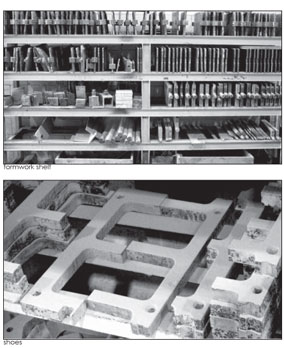

Formwork

The shape of a block is formed by the components contained within the plunger. These include the face molds which create the exterior of the block, the core formwork which creates the block cores and the shoes, which finish the top of the block. The face molds are regularly replaced due to wear and are relatively inexpensive. Because of their short lifespan and affordability, we focused our investigation on creating blocks that exploit possibilities dependent on these components.

Size

Concrete blocks are available in a range of sizes. While there are clear advantages to using blocks of varying size to develop the visual and tactile qualities of a wall, the size and weight of blocks also impacts the cost of labor during installation. In order to maintain the economic advantages of typical block construction we limited our investigation to blocks of the most typical size, 8”x8”x16”.

Bonding

The structural integrity of a concrete block wall is dependent on its bonding pattern. Creation of a structurally monolithic block wall depends on establishing a bonding pattern with interlocking cores that can be reinforced and filled with grout. This works best with a running bond. Therefore, we limited our investigation to configurations of block within a running bond pattern.